Areas of Expertise

what area of expertise are you looking for ?

Sizing / Preliminary calculations

Conveyor calculation internal software

Thermodynamic & hydraulic simulations, mass transfer, heat transfer (HYSYS, HTFS).

Heat exchange calculation

Mechanical calculation

- Pressure vessel

- Piping

- Metallic Structure

Feasibility study

Finite element analysis

Design

Calculations, design studies, finite element

2D, 3D drawings and TEKLA

Electrical / Automation / Remote maintenance

Civil work

ATEX / Fire Detection and Fighting System / Dusting

Sampling

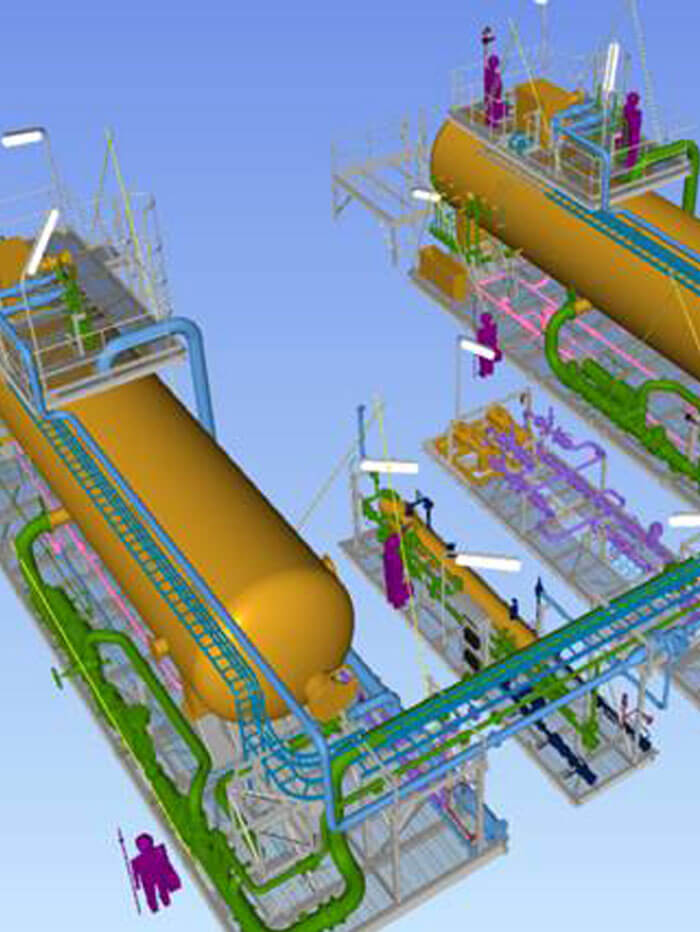

Design studies using recognised CAO softwares such as AUTOCAD, PDS, PDMS and SOLIDWORKS.

Determination of utilities required for unit operation.

Measurement of main process properties (pressure, flow, level, temperature). Use of control devices (valves, pumps…).

Control System (PLC). Programming using functional analysis in accordance with the client specifications.

PFD

P&ID

3D model reviews

R&D

Process Development

FEED Studies

Product Development

Pilot Installation

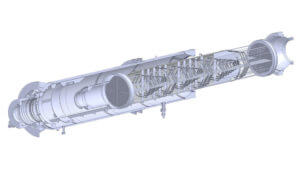

STEEL METALWORK

We offer equipment to suit your specific requirements:

- Pressure vessels

- Exchangers

- Skid units

- Steel skid structures

- Custom designed heavy fabricated equipment

- Thick walled fabricated equipment

Piping

Experts in our specific area of work, we are capable of offering complete piping design in our drawing office, manufacturing in our workshops to the installation on site.

Whether in carbon steel or stainless steel, we adapt to meet your specific piping diameter requirements.

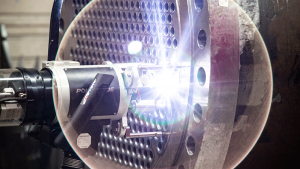

Welding

All the fabrication workshops of the IWF Group have expertise in welding whether it is:

Automatic

- TIG Orbital

- Robots

Manual

- MIG / MAG

- TIG

- Coated electrode

Mechanised

- SAW welding arm

- PAW welding arm

- TIG automatic welding arm

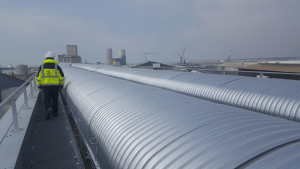

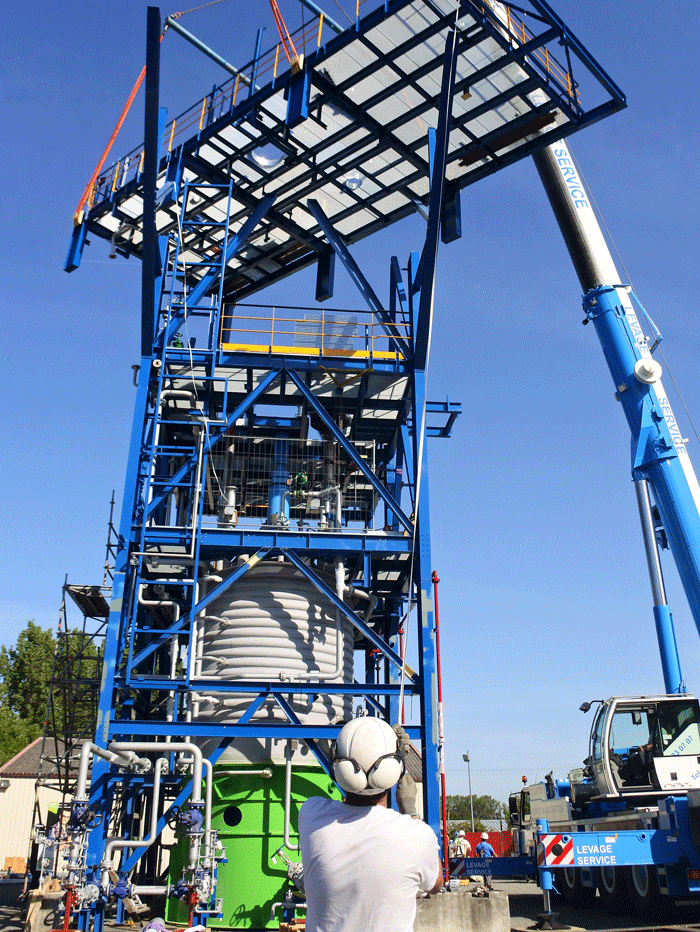

Metal Framework

The IWF Group manufacturing workshops has expertise in structural steelwork.

Endowed with high manufacturing and handling capabilities with an alongside quay loading dock, a lifting capacity of up to 200 tonnes and a 16 m clearance under hook , all your steel framework projects are achievable.

- Support: from 1 M to 24 M

- Tower: from 5 M to 30 M

- Bridge: from 3 M to 42 M

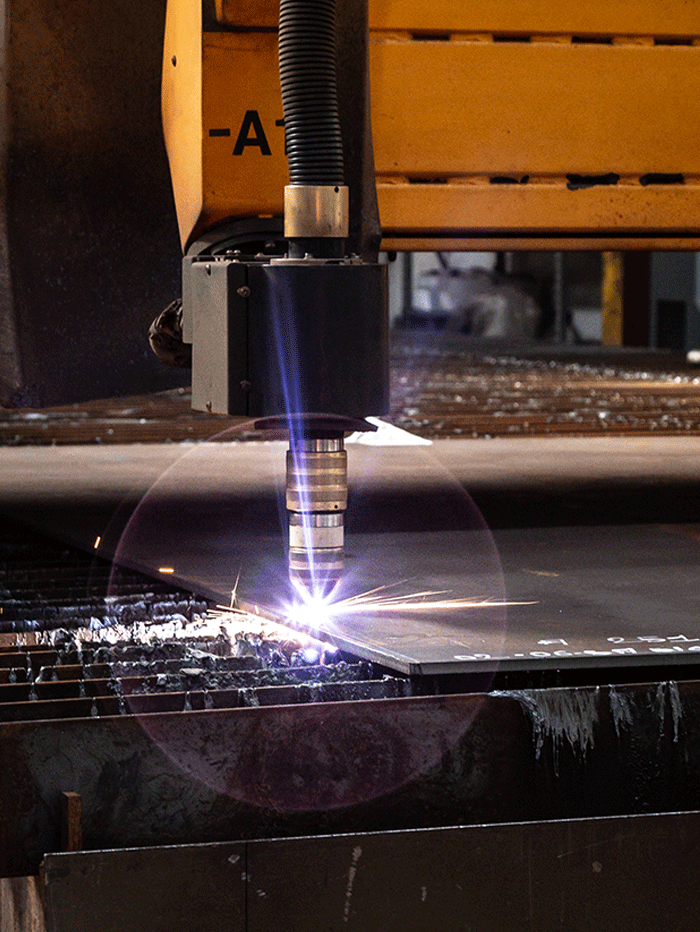

Cutting / Machining

Our manufacturing workshops are equipped with all the necessary cutting and machining equipment required for your projects:

- Plasma cutting machine - MICROSTEP COMBICUT (unique in Europe) – Sheet metal, tubes and bevel end plates

- 3-head oxy plasma cutting machine – Sheet metal, tubes and bevel end plates

- Machining centre: Internal / external machining - Chamfering - Drilling - Tapping - Internal / external filtering - Internal / frontal / external Grooving - Knurling - Cutting

Surface Treatment

Our manufacturing workshops have dedicated surface treatment areas suitable for large size equipment:

- Shot-blasting shop

- Paint spray shop

- Stripping/passivation area

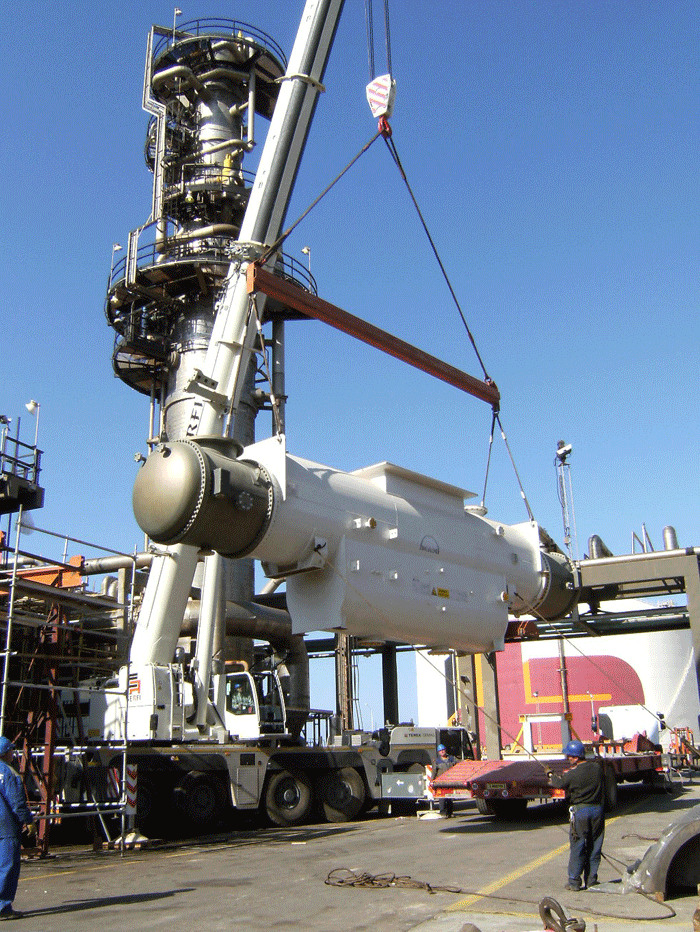

Handling Equipment

Our fabrication workshops are equipped with:

- 100m long ship loading dock

- 16m clearance under hook

- 100 tonnes lifting capacity

Assembly

Our site teams are up made up of qualified site managers as well as qualified fitters. We ensure the assembly of all the equipment directly on your production site.

We also provide a supervision service around the world to coordinate assembly locally.

Subcontractor Management

Our site teams ensure efficient management of the subcontractors on site.

Handling

Heat insulation

Electricity

Instrumentation

Civil engineering

Start-up

Our qualified assembly and supervision teams ensure installation, commissioning and start-up worldwide.

Mechanical testing

Fluids

Electrical power

Instrumentation

Regulation

Performances

Services: expertise, training, on-site and remote troubleshooting, retro-fitting, spare parts, used equipment…

Services

Requirement analysis

Diagnostic

Expertise

Failure prevention

Programming of preventive inspection

Training

On-site and remote troubleshooting

After-sale service

Retro-fitting

Spare parts

Used equipment

Control

Certification level: COFREND 3

3D SCAN

Site tests

Dimensional check of pressure vessels and skids

Direct / indirect visual testing (VT)

Internal and external welding visual inspection

Piping Inspection

Positive Material Identification (PMI)

Chemical analysis of key components, filler material and welding

NON-DESTRUCTIVE TESTING (NDT)

Penetrant testing: Surface controls

Magnetic particle testing: Surface controls

Ultrasonic testing: Volumetric checks

ANTICORROSION PROTECTION

Surface preparation check (Bresle test, roughness, chlorides, etc.) and atmospheric conditions

Dry film thickness test

Paint pull-off adhesion test

HARDNESS

Hardness measurement of base materials and weld

Project Management

PLANNING

Coordination of all service providers involved in the project

CONTRACTUAL

Drafting of contract ensuring the protection of all parties

FINANCIAL

Cost optimisation

RELATIONAL

Regular follow-up and reporting to Client

Safety of supplied installations.

Risk management assessment.

Compliance with standards: HAZOP, HAZID, SIL, ATEX, CE

Functional analysis

HAZOP analysis